Dec. 15, 2023

Machinery

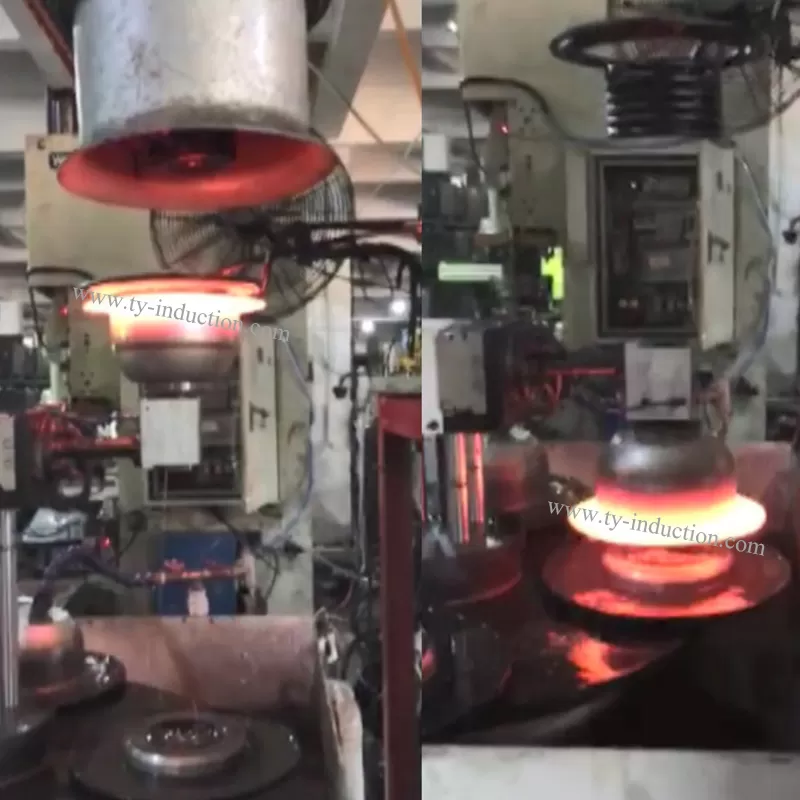

Induction annealing machine has revolutionized various industries, providing efficient heat treatment processes. However, a comprehensive understanding of their limitations is crucial for optimizing their use. In this article, we delve into the constraints of induction annealing machines, shedding light on aspects that demand attention and consideration.

One primary limitation of induction annealing machines lies in their material compatibility. While these machines excel in treating ferrous metals, they may fall short when dealing with non-ferrous materials. The inductive heating process relies on the material's magnetic properties, posing a challenge for substances lacking magnetic susceptibility.

Despite their precision in many applications, induction annealing machines may face limitations in achieving ultra-precise temperature control. This becomes particularly pronounced when dealing with small or intricate components, where maintaining an exact temperature becomes challenging. The thermal uniformity across the entire workpiece can be affected, impacting the overall quality of the annealing process.

Induction annealing machines are renowned for their energy efficiency, yet they are not exempt from limitations in certain scenarios. The power consumption can escalate when dealing with larger workpieces or prolonged heating durations. Understanding these limitations is crucial for industries aiming to optimize their energy usage and minimize operational costs.

While induction annealing machines are widely used for surface hardening applications, they may encounter limitations in achieving consistent hardness levels. Factors such as material composition and geometry can influence the depth of hardening, leading to variations in the final product. Manufacturers must carefully assess these limitations to ensure uniform hardness across all treated components.

Induction heating machine relies on electromagnetic fields, and this can result in challenges when dealing with components of intricate geometries. The uneven distribution of heat may occur in complex structures, affecting the overall annealing outcome. Understanding the limitations in handling intricate designs is crucial for industries where component complexity is a common feature.

Every technological marvel has its upkeep demands, and induction annealing machines are no exception. Regular maintenance is imperative to ensure optimal performance, but this comes with associated downtime. Businesses relying on continuous production must factor in these maintenance requirements and plan accordingly to avoid unexpected disruptions.

For industries with space constraints or those requiring portable heat treatment solutions, the size and portability of induction annealing machines become limiting factors. Larger machines may not be feasible for compact workspaces, prompting the need for alternative heat treatment methods. Understanding the spatial requirements is vital for businesses aiming to integrate induction annealing seamlessly into their operations.

In conclusion, while induction annealing machines have revolutionized heat treatment processes, it is crucial to recognize their limitations. From material compatibility challenges to precision issues and maintenance demands, a nuanced understanding of these constraints is imperative for optimizing their use across diverse industries. By acknowledging and addressing these limitations, businesses can harness the full potential of induction annealing machines while mitigating potential drawbacks.

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )