Sep. 25, 2023

Chemicals

An anti-corrosion primer, also known as a rust-inhibiting primer or corrosion-resistant primer, serves the primary purpose of protecting metal surfaces from corrosion or rust. Here's what it does:

Corrosion Prevention: The main function of an anti-corrosion primer is to create a protective barrier between the metal substrate (such as steel or iron) and the external environment. It prevents moisture, oxygen, and other corrosive agents from coming into direct contact with the metal.

Adhesion: Anti-corrosion primers typically have good adhesion properties, allowing them to firmly bond to the metal surface. This adhesive quality ensures that the primer remains in place, forming a continuous and effective protective layer.

Surface Preparation: In addition to corrosion protection, these primers often serve as a surface preparation layer. They can smooth out rough or uneven metal surfaces and improve the adherence of subsequent paint or coating layers.

Barrier Properties: Anti-corrosion primers are formulated with corrosion-inhibiting compounds, such as zinc, chromates, or other rust-resistant materials. These compounds create a barrier that makes it difficult for oxygen and moisture to reach the metal, inhibiting the corrosion process.

Enhanced Durability: By preventing corrosion, these primers help extend the lifespan of metal structures, equipment, or surfaces. This is especially important in applications where exposure to harsh environmental conditions or corrosive substances is common.

Compatibility with Topcoats: Anti-corrosion primers are typically designed to be compatible with various topcoats, such as paints or protective coatings. This means that after applying the primer, a layer of paint or coating can be added for additional protection and aesthetic purposes.

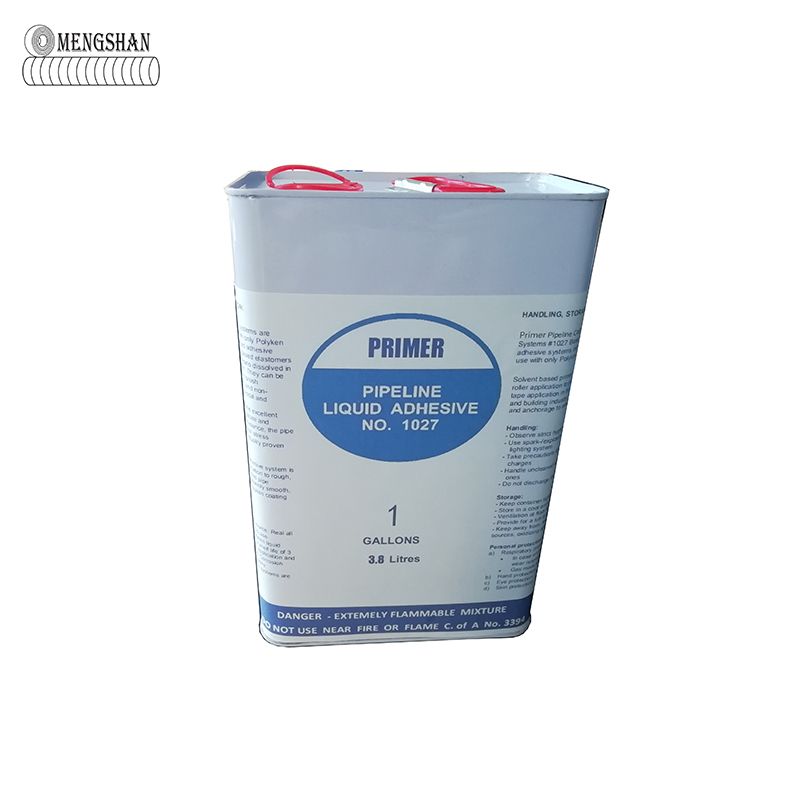

Versatility: Anti-corrosion primers are used in a wide range of industries and applications, including automotive, marine, construction, and industrial settings. They are applied on everything from bridges and pipelines to vehicles and machinery to prevent corrosion.

It's important to note that the effectiveness of an anti-corrosion primer depends on factors such as the type of metal being protected, the environmental conditions it will be exposed to, and the quality of the primer itself. Regular maintenance and inspection are also essential to ensure long-term corrosion protection.For inquiries or to connect with a trusted supplier, please do not hesitate to contact us today. Your metal assets deserve nothing less than the best in corrosion protection.

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )